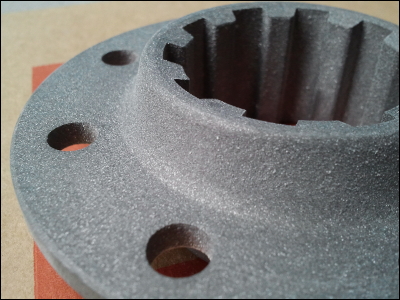

Heavy zinc phosphating is used for long-time corrosion protection of iron, steel and cast parts. It is suitable for hundreds of kinds of parts working in oily environment

such as auto parts, machine parts, fasteners, gear, bolts, screws, weapon parts.

Metal parts should be cleaned from rust, oil and other impurities before phosphating. The protective zinc phosphate coating process requires high temperature and high bath

concentration. Application temperature is in the range of 70-95 ºC.

Compared to other phosphate coating types, a high concentration bath is prepared and high values are maintained. Coating weight formed on metal is usually between

15-35 g/m². After phosphating, the parts goes in protective oil bath. Protective oil selection is important to obtain high corrosion resistance.

During the preparation and operation of protective zinc phosphating baths, total acid, free acid, temperature, iron point values should be checked, and regular additions

should be made according to the results obtained.