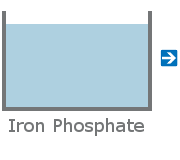

When planning the coating line, details such as process temperatures, shapes of the parts to be coated, and working intensty should be taken into consideration. The appropriate iron phosphate product that will provide the required salt test and corrosion resistance should be selected.

Iron Phosphate

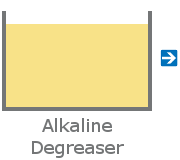

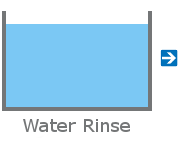

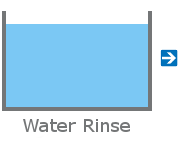

Coating Line OrderSpray Iron Phosphate Coating Line Flow Chart - 1

Spray Iron Phosphate Coating Line Flow Chart - 2

Notes:

- Acidic solution treatment baths should be made of durable stainless steel material.

- Alkaline and neutral solution treatment baths can be made of stainless steel or durable polypropylene or polyethylene.

- In case of using tap water or hard water, care should be taken to use passivation product to avoid

paint adhesion problems.

- In order not to damage the phosphate coating, the drying temperature should not exceed 120 °C.