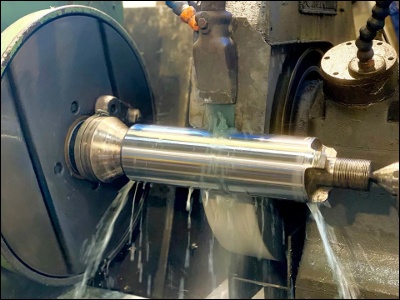

Metal parts processed in grinding machines become hot due to friction during grinding. The solution with added grinding chemical in the

reservoir of the grinding machine provides sliding between the abrasive stone and the metal. Friction and heating are reduced, parts can

be processed easily.

End products processed in cylindrical grinding, surface grinding and similar type grinding machines and machine parts in contact acquire a

protective feature against corrosion.

Adverse effects such as bacterial growth and odor that occur with the use of boron oil are not seen in water-based cutting / coolant products.

It has the advantage of using a lower concentration.

Slightly alkaline product used for iron, steel and cast parts in grinding machines. It is added into cooling water in the machine reservoir. Good alternative to boron oil. Does not cause unwanter odor because of formation of bacteria. It can work at ambient temperature. Protects both the machine and the machined metal part against corrosion. Its concentration can be measured with the help of refractometer.

Transparent synthetic product used for machining works for iron, steel and cast parts. It is added to the coolant. It minimizes heating by providing gliding between the machine and the metal part. It is a good alternative to boron oil in order not to create odor from bacteria. Cooling solution can be easily checked and controlled with refractometer analysis.